PACC Floorservice has specialized in assessing flatness for all types of floors, varying from concrete floors in high-rise warehouses to cement screeds in house-construction. The flatness of a floor is very important with regard to its functionality, regardless of the application, such as floors for warehouses with racks up to 15m¹ height and more, but also with regard to the finish that will be applied.

Every floor has to meet different requirements, depending among other things on the way it is used. This means, that there are also different standards that determine if a floor is flat enough or not. PACC Floorservice has the ability and the expertise to perform the correct measurements.

The measurements we carry out will be adjusted to the set flatness requirement. These can be according to the German DIN 18202 (2005) or DIN 15185 (1991) VDMA (2010) which are often used as international standard, according to the Belgium WTCB TV 204 (1997), a national standard or another, but of course also according to our own Dutch Standard, the NEN 2747 (1999).

Flatness can be defined as measured from a plane or through a gap under a straightedge, however both options require a different method.

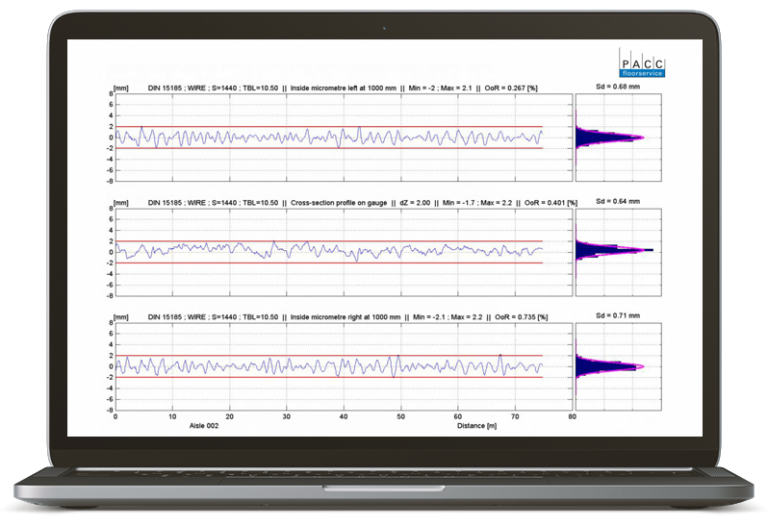

When measuring the floor through the FloorProfiler the stored can be converted directly from the certified server into results, making the measurement results 100% reliable. A measurement by means of the FloorProfiler is called a continuous measurement. It gives a clear picture of the floor profile.

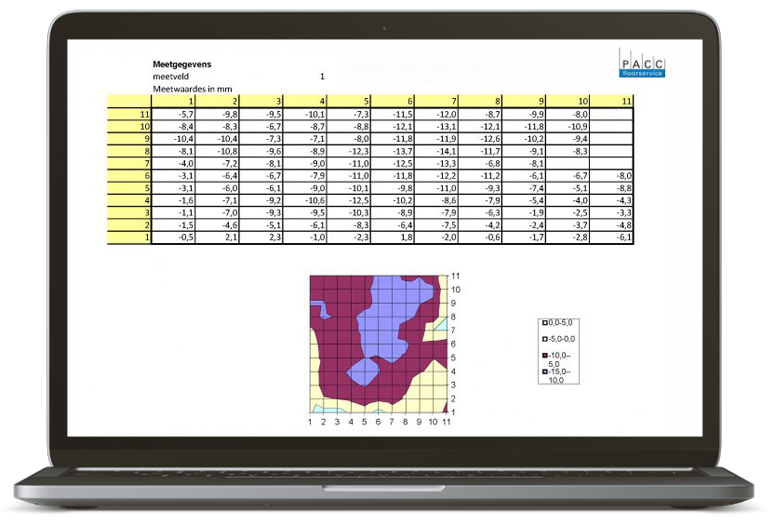

A static measurement, such as according to the NEN 2747, is based on height differences measured from a horizontal plane. By taking a couple of measurement points according to a specified distance, one gets height differences, which must be tested to the required flatness class and the corresponding criterions.

All measurement results, including conclusion and graphic display are converted into a clear report.

Less wear and tear of the work floor

Safe work environment

More time savings

Less wear and tear of machines

Less employees

The flatter a floor is, the less unrest an operator experiences with his truck and less vibrations result in a higher speed. Of course we are not talking about tens of kilometers an hour, yet differences that seem small can bring a decent result.

Warehouses are becoming increasingly efficient thanks to forklifts that can store and/or collect goods at great heights. While driving, the driver takes his complete cabin many meters up. If a floor isn’t flat, a vehicle starts wobbling. You won’t hardly notice this just above the ground but as you go further up, it will feel like you are in a rollercoaster and the situation can become unsafe or the efficiency can be negated.

Measuring the floor and all things that are related, is a large process. At your first visit we will clearly explain the entire process from start to finish. The follow-up steps largely depend on the type of floor, but also on how long a production can stand still for maintenance work.